Marine Vibration Analysis and Balancing

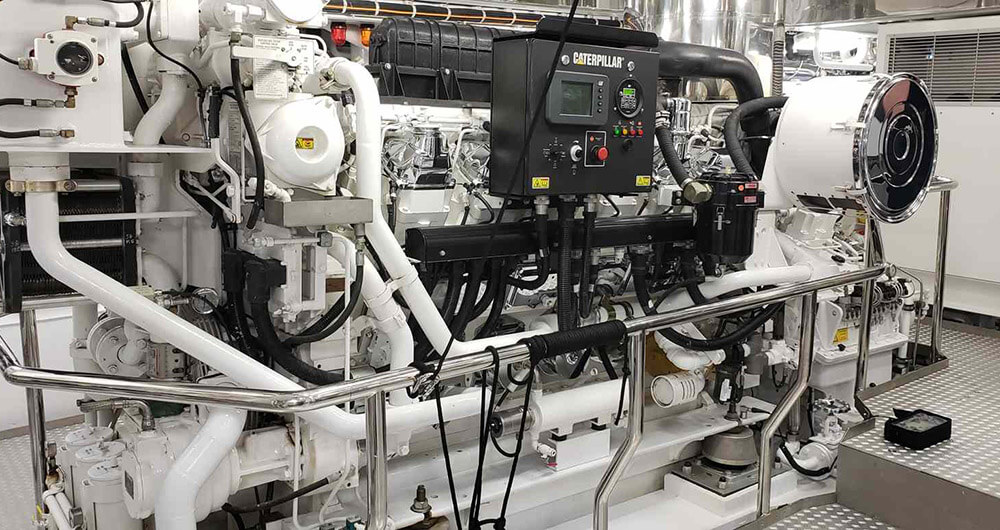

With a background in Naval critical machinery operations and reliability, we understand first-hand the importance of preventing machine failure or power loss while at sea. Datum RMS serves marine clients all over the world.

Why Choose Us?

Our vibration analysts record data in the marine environment to evaluate the machine condition and isolate the cause of faults before expensive shipyard repairs.

- Certified, highly trained and experienced team

- Yachts, military vessels and commercial vessels

- Best-in-industry equipment that is calibrated regularly

- High level of precision measurement

OUR SERVICES

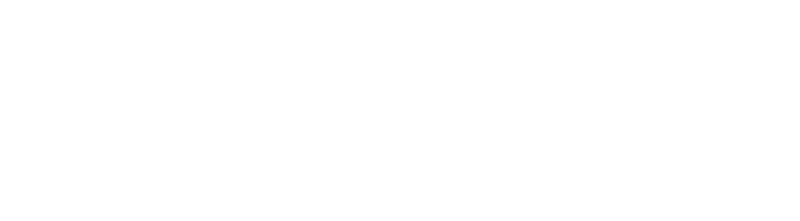

Scheduled Analysis Vibration Monitoring

Through scheduled vibration monitoring, you can find problems early, reducing your trips to the shipyard.

Owner Trials & Pre-delivery Testing

Datum RMS recommends that our marine vibration surveys begin here to provide a baseline of vibration data. We will then use this for acceptance testing and the future diagnosis of problems while performing ongoing condition monitoring of the vessel’s machinery.

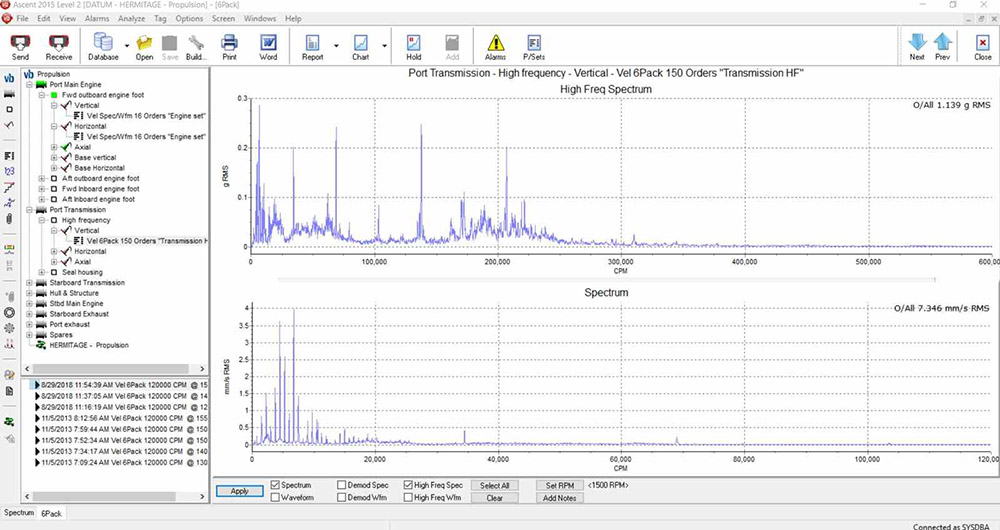

Modal Shape and Operating Deflection Shape (ODS) Surveys

As part of our diagnostic survey offerings, our modal shape and ODS surveys evaluate structural issues on hulls and nautical support structures. Our experienced team serves clients nationally and internationally through prevention, diagnostic testing and issue resolution. Datum RMS uses MeScope software tools.

Pre- and Post-Maintenance Surveys

Datum RMS can perform pre- and post-works vibration surveys around shipyard maintenance periods. These sets of data allow the vessel managers to document improvements for presentation to owners and also provide a baseline set of data for future diagnostics. These surveys are adjustable in scope and can include A-weighted sound measurements taken to class rules.

Diagnostic Surveys

Datum RMS utilizes diagnostic surveys to detect the source of a vibration issue before a shipyard period.

Top insights provided by marine diagnostic surveys include:

- Shaft couplings, flexible machine couplings that are misaligned

- Bearings or gears that are misaligned / worn

- Rolling-element bearings that have deteriorated in transmissions and thrust bearings

- Rotating components experiencing unbalance

- Fans, pumps and blower aerodynamic / hydraulic problems

- Motors with unbalanced magnetic forces causing electrical issues

- Machinery soft-foot conditions

- Rotating components like “V” belt pulleys or gear eccentricity

- Shaft bends

- Underwater running gear misalignment, such as propeller struts

- Main engine misfire problems

- Rubbing

- Looseness

- Propeller defects

- Resonance

At the completion of our marine diagnostic surveys, you will receive complete, written reports with detailed findings and recommendations on how to resolve issues.