Industrial Vibration Analysis and Balancing

We offer a comprehensive set of industrial vibration services:

Did you know that a machine can be running into catastrophic failure, although it appears to be operating normally? We work to the accepted standards included in ISO 1940 (ANSI S2.19-1975) and provide vibration analysis and balancing services for compressors, HVAC units, coupling assemblies, motors, vertical pumps, cooling towers, inert gas fans, and more.

Why Choose Us

Increase your return on investment!

- Our industrial vibration monitoring programs can provide substantial savings by catching areas of concern before they develop into costly malfunctions.

- This advance warning can reduce damage to your machines.

- Using state-of-the art vibration analysis tools, we gather vibration measurements to identify individual machine’s faults in addition to the root cause.

- Our team will inform you of the recommend solutions to remedy any issues discovered.

Diagnostic Surveys

Datum RMS provides diagnostic surveys for all rotating machinery. These surveys provide insights into defects or fault conditions and are customized for each machine that is tested.

Top insights provided by Datum RMS diagnostic surveys include:

- Wearing of gears

- Couplings, bearings or gears that are misaligned

- Rolling-element bearings that have deteriorated

- Rotating components experiencing unbalance

- Fans, pumps and blower aerodynamic / hydraulic problems

- Motors with unbalanced magnetic forces causing electrical issues

- Machinery soft-foot conditions

- Rotating components like “V” belt pulleys or gear eccentricity

- Looseness

- Rubbing

- Resonance

Commissioning Surveys

Through this process, Datum RMS designs comprehensive tests for your machinery. With the data provided you can ensure that the machinery meets your acceptance standards prior to commissioning.

Benefits of Commissioning Surveys:

- Monitor operational conditions

- Ensure the early detection of defects

- Implement a properly planned maintenance schedule

- Reduce costly downtime

- Increase productivity

- Lower operational and maintenance costs

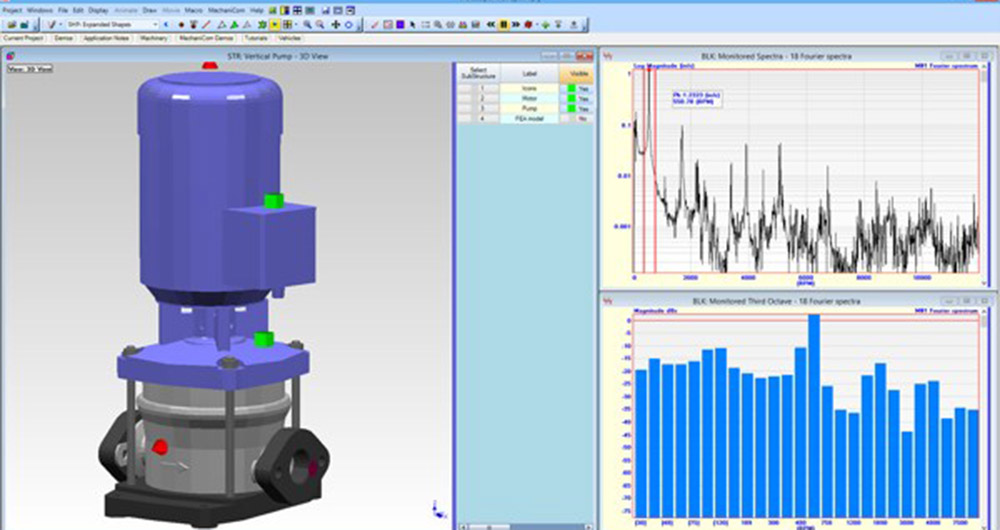

Modal Shape and Operating Deflection Shape (ODS) Surveys

As part of our diagnostic survey offerings, our modal shape and ODS surveys identify natural frequencies and their mode shape. The customized surveys provide the Datum RMS team data to create engineered changes to structures to eliminate resonance and structure related reliability issues. Datum RMS uses MeScope software tools.

Scheduled Vibration Analysis and Monitoring

Ongoing monitoring of machinery provides you with data insights that allow us to find problems early. We are able to spot trends through ongoing measurement and detect abnormalities before they are serious issues.